Top Guidelines Of Premier Aluminum Llc

Table of Contents4 Simple Techniques For Premier Aluminum LlcRumored Buzz on Premier Aluminum LlcSome Of Premier Aluminum LlcWhat Does Premier Aluminum Llc Do?

(https://justpaste.it/1zrj7)Generally, a buyer's primary duty was to find professional and responsive vendors. Sometimes, purchasers thought that any supplier ready to contractually fulfill the acquisition need was qualified. Nonetheless, using reduced price and unqualified providers can trigger top quality issues, and lost time and cash in the future. To help you through the process, right here are some points to consider when choosing the best metal spreading distributor.

A business that only utilizes the investment casting process will certainly try to offer you on why that process is best for your application (Aluminum Metal casting). What if utilizing the sand casting procedure is best for you and your needs? Rather, search for a provider that uses an array of casting procedures so the most effective choice for YOU is picked

If collaborating with a single resource for every one of your spreading needs is essential to you, the supplier needs to be varied in its capacities. When incorporated with various other incorporated capacities, this can help simplify and compress the supply base. When choosing the best casting vendor, mindful factor to consider must be provided to high quality, service, and price.

Some Known Questions About Premier Aluminum Llc.

Purchasers increasingly choose spreading vendors that have machining abilities. This can stay clear of conflict if issues are found during machining. If a 3rd party is machining, it might lead to "finger-pointing" regarding who is at fault. Is it a casting problem or a machining concern? If the spreading provider uncovers a problem throughout machining, the issue is settled faster without any dispute over whose fault it is.

What do you require from your spreading supplier? Are you looking for a person to just deliver a steel part to your doorstep or do you need much more?

Some factories are limited or specialized. Make sure the distributor can satisfy all your material or alloy needs to eliminate the requirement for numerous distributors.

Little Known Questions About Premier Aluminum Llc.

Research study the vendor's web site. Talk to a sales associate or company partner.

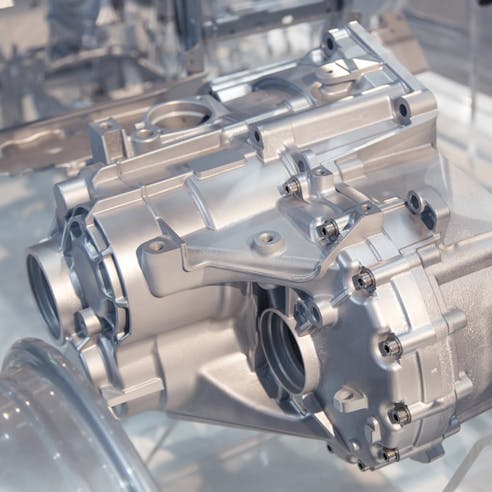

Light weight aluminum is likewise lightweight and has excellent rust resistance, making it ideal for applications where weight and resilience are crucial aspects. Additionally, light weight aluminum spreading is an discover this economical technique of manufacturing, as it requires much less energy and resources than other approaches. Iron casting, on the other hand, involves putting molten iron into a mold to produce a desired shape.

The Buzz on Premier Aluminum Llc

Iron spreading is additionally able to endure heats, making it appropriate for usage in applications such as engine parts and commercial equipment. Iron spreading can be more costly than light weight aluminum casting due to the higher expense of raw products and the power required to melt the iron. When choosing in between light weight aluminum spreading and iron spreading, it is essential to take into consideration the details needs of the application.

In verdict, both aluminum casting and iron spreading have their very own special advantages and negative aspects. There are 3 sub-processes that fall under the classification of die casting: gravity die casting (or irreversible mold and mildew casting), low-pressure die casting and high-pressure die spreading. To obtain to the ended up item, there are 3 primary alloys utilized as die casting material to select from: zinc, aluminum and magnesium.